Finding the best scope rings for a Picatinny rail isn't about chasing one specific "best" product. It's about finding the right match for your rifle, your scope, and how you plan to use them.

The perfect set of rings depends on three core things: the material they're made from, the right height to clear your barrel, and the mounting style that fits your needs.

How to Choose the Best Scope Rings for Your Rifle

Think of your scope rings like the tires on a race car. You can have the most powerful engine and a perfectly tuned chassis, but without a solid connection to the track, none of it matters. Your scope rings are that critical link. They're what lock your high-dollar optic and precision rifle together into one cohesive, accurate system.

Get this choice wrong, and you'll be chasing a wandering zero forever. But get it right, and you've laid the foundation for tack-driving consistency shot after shot.

The whole process really boils down to your rifle's job. A featherlight mountain rifle built for backcountry hunts has totally different requirements than a heavy benchrest rig chambered in a magnum caliber that can ring steel at a mile.

Key Decision Factors

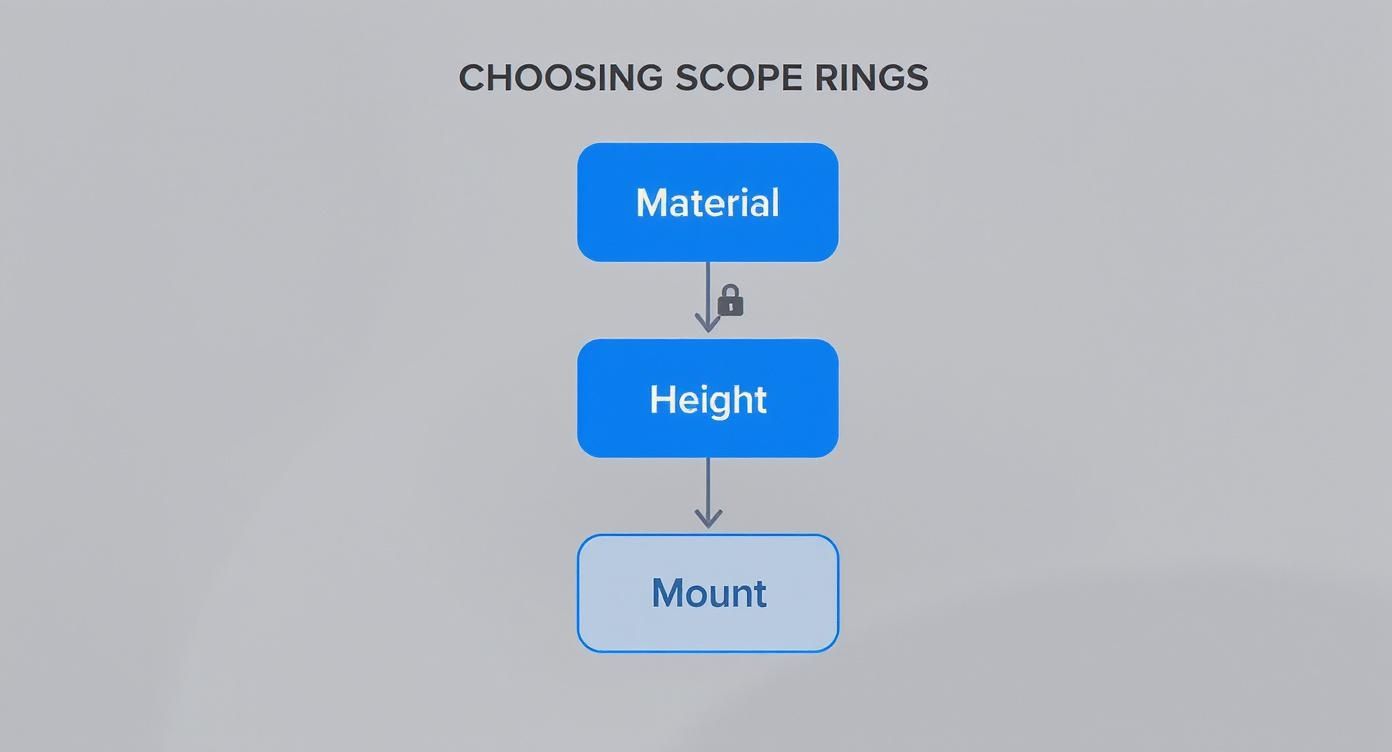

To keep things simple, just focus on these three areas:

- Material Construction: The big choice here is between aluminum and steel. For most hunters, a quality set of 6061-T6 aluminum rings is perfect—they're lightweight, strong enough, and won't rust. But if you're mounting a heavy scope on a hard-recoiling rifle, steel is king. It’s denser and more rigid, providing the brute strength needed to keep everything locked down.

- Ring Height: This is all about your scope's objective lens (the big one at the front) and your rifle's barrel. The goal is simple: mount the scope as low as you can without the objective bell actually touching the barrel. A lower mount promotes a more natural and repeatable cheek weld, which is a cornerstone of good marksmanship.

- Mounting System: You've got two main paths. Standard mounts use screws to clamp everything down for a "set it and forget it" installation. The other option is a quick-detach (QD) system, which uses levers. QD mounts are fantastic if you want the flexibility to swap optics or quickly pop your scope off to use your iron sights.

This decision tree helps visualize how to narrow down your options based on what you need.

As you can see, what you’re doing—hunting, competing, or tactical work—is the starting point that drives every other choice you'll make.

To help you remember the key variables at a glance, here’s a quick summary table.

Quick Guide to Picatinny Scope Ring Selection

| Factor | Common Option A | Common Option B | Primary Consideration |

|---|---|---|---|

| Material | Aluminum (6061-T6) | Steel | Weight vs. Maximum Strength |

| Height | Low / Medium | High / Extra-High | Objective Lens Diameter & Barrel Profile |

| Mount Style | Standard (Screws) | Quick-Detach (QD Levers) | Permanent Setup vs. Flexibility |

This table should give you a solid mental checklist when you're browsing for a new set of rings.

By thinking through each of these elements, you stop just buying a part and start building a truly optimized shooting system. This mindset ensures every single component, from the glass down to the rings, is working in perfect harmony.

In the end, the best scope rings are the ones you never have to think about. They just do their job, quietly and reliably, so you can focus on making the shot. For hunters, making sure all your gear works together seamlessly is a huge part of being successful in the field.

To dive deeper into setting up your kit, check out our guide on hunter essentials and must-have gear. This kind of foundational knowledge will help you build a complete system that won't let you down when it counts.

Why Scope Rings Are the Foundation of Your Accuracy

Let's think of your rifle system like a custom-built house. The action and barrel are the precision-engineered frame, and that high-end scope is the advanced security system letting you see every detail. But what connects it all? The scope rings. They are the concrete foundation holding everything together.

If that foundation is weak, cracked, or poorly set, the entire house is compromised. It doesn't matter how much you spent on the rifle or the glass—a cheap set of scope rings will sabotage the whole system, leading to nothing but frustration. They're far more than a simple accessory; they are the critical link that makes your rifle and optic work as one.

Choosing the wrong rings has immediate, painful consequences. You might spend an entire day at the range chasing a "wandering zero," where your point of impact shifts unpredictably with every shot. That isn't just annoying; it kills your confidence and can lead to unethical shots when hunting.

The Hidden Costs of Poor Quality Rings

The problems with subpar rings go way beyond just being frustrated at the range. A cheap or poorly machined set can permanently damage your expensive scope.

When rings aren't perfectly aligned, they squeeze the scope tube with uneven pressure. This can cause anything from minor cosmetic scuffs to serious internal damage that ruins the optic’s adjustments and clarity for good. It’s like trying to support a straight steel beam with two crooked pillars—the stress has to go somewhere, and your scope tube will pay the price.

- Loss of Zero: This is the classic symptom. Rings that move even a thousandth of an inch under recoil will throw your shots way off target.

- Inconsistent Grouping: You'll never shoot tight, repeatable groups because the scope isn't held in a stable, consistent position.

- Scope Damage: Uneven clamping pressure can crimp, dent, or even bend the scope tube, potentially destroying a very expensive piece of equipment.

A solid mounting system is designed to do one job above all else: hold the scope in perfect alignment with the rifle's bore, shot after shot, regardless of recoil or rough handling in the field.

This is why investing in quality rings is a direct investment in your rifle's accuracy. It's not about burning money; it's about building a dependable system you can trust completely, whether you're lining up for a competition-winning shot or observing wildlife from a distance.

For those using advanced tools like cellular trail cameras, a reliable rifle system is just as important. To learn more about getting clear and steady shots in the field, check out our essential wildlife photography tips for beginners.

Market Growth Reflects Rising Importance

The shooting community's growing appreciation for this is showing up in the market data. The Picatinny rail rings market was recently valued at around $250 million, which tells you just how seriously shooters are taking this component.

With a projected growth of nearly 7% annually through 2033, it's clear that both hobbyists and professionals are prioritizing solid mounting solutions. This trend is driven by better manufacturing and a rising interest in precision shooting. Discover more insights about this growing market trend.

Ultimately, the best scope rings for a Picatinny rail give you peace of mind. They become an invisible, yet essential, part of your rifle that you never have to think or worry about. When you have that level of trust in your gear, you can focus 100% on your marksmanship, knowing your foundation is rock-solid.

Getting to Know Your Scope Ring Specs

Diving into the world of scope rings can feel like trying to crack a code. You'll hear terms like "tube diameter," "saddle height," and see material designations like "7075-T6" tossed around. While it sounds technical, understanding these details is what separates a rock-solid setup from a frustrating day at the range.

Let's cut through the jargon and focus on the three specs that truly matter: scope tube diameter, ring height, and material. Nail these, and you’re well on your way to a secure, accurate, and reliable rifle.

H3: Scope Tube Diameter: The First Checkpoint

The first and easiest spec to figure out is your scope tube diameter. This is simply the diameter of the main tube on your scope—the part the rings actually clamp onto. Think of it like buying a hat; you need to know your head size first.

Most modern scopes fall into one of three common sizes:

- 1 inch (25.4mm): The old-school standard, still very common on hunting scopes and more traditional rifle builds.

- 30mm: This has become the go-to size for just about everything else, from tactical to long-range scopes. The wider tube allows for more internal adjustment and better light transmission.

- 34mm: You'll find this on high-end, extreme long-range scopes. It offers the absolute maximum internal adjustment range for dialing in those far-off shots.

There's no fudging these numbers. A 30mm ring won't hold a 1-inch scope securely, and trying to force it is a surefire way to damage your expensive optic. Always check your scope's manual or product page to confirm its tube size before you even think about buying rings.

H3: Getting Ring Height Just Right

Ring height is where a lot of people get tripped up, but the goal is straightforward: mount your scope as low as possible without the big front lens—the objective bell—touching the barrel. A lower mount helps you get a natural, solid cheek weld on the stock, which is absolutely critical for consistent accuracy.

To figure out the right height, you'll need two key measurements:

- Your scope's objective lens outer diameter. This isn't just the lens size (like the "50" in 5-25x50). You need to measure the full, outside diameter of the bell housing with a caliper.

- Half of your scope's tube diameter. This is 15mm for a 30mm tube or 12.7mm for a 1-inch tube.

The basic math looks like this:

(Objective Diameter / 2) - (Tube Diameter / 2) = Minimum Ring Height

Let's run through a quick example. Say you have a 30mm tube scope with a 56mm objective bell.

(56mm / 2) - (30mm / 2) = 28mm - 15mm = 13mm

You'd need rings with a "saddle height" of at least 13mm. This measurement tells you how high the bottom of the scope tube sits above the rail, ensuring the objective bell has enough room to clear the barrel. It's always a good idea to add a couple of millimeters to this minimum for lens cap clearance.

Scope Ring Height Calculation Guide

Here's a simplified table to help you estimate the ring height you'll need. Always measure your specific setup, as barrel contours and rail heights can vary.

| Objective Lens Diameter | Typical Ring Height Needed | Notes |

|---|---|---|

| Up to 42mm | Low (0.75" - 0.85") | Usually safe for standard barrel profiles. |

| 44mm - 50mm | Medium (0.90" - 1.10") | The most common range; provides clearance for most setups. |

| 56mm and larger | High (1.20" - 1.50") | Necessary for large objective lenses, especially on heavy barrel rifles. |

This table provides a great starting point, but nothing beats breaking out the calipers for a precise measurement.

H3: Choosing Your Material: Aluminum vs. Steel

The material your rings are made from dictates their weight, toughness, and price. It really comes down to two choices: aluminum or steel. Each has its place.

- 6061-T6 Aluminum: This is your standard, workhorse aluminum. It’s lightweight, affordable, and plenty strong for most hunting rifles, even standard magnum calibers.

- 7075-T6 Aluminum: A serious step up from 6061, this high-grade alloy offers nearly the strength of steel at a fraction of the weight. It's the premium choice for hard-use tactical rifles and precision builds where every ounce matters.

- Steel: When absolute strength and recoil resistance are the top priorities, nothing beats steel. It’s heavy, but its density and rigidity are perfect for heavy-recoiling magnum rifles, dangerous game setups, or any situation where failure is not an option.

For a lightweight mountain rifle, 7075-T6 aluminum is the perfect balance of strength and weight. But if you're building a .338 Lapua Magnum precision rig, the extra mass and clamping force of steel rings provide peace of mind and unmatched stability.

These principles of optical stability aren't just for rifles. They apply equally to spotting scopes, where a solid mount is critical for clear viewing. In fact, many of the lessons in our spotter scope reviews touch on the importance of a stable foundation. Arming yourself with this knowledge will help you read any product description with confidence and choose the right rings for your optic.

How Quality Rings Ensure Rock-Solid Zero Retention

A scope mount has one job, and it’s a big one: hold your scope in the exact same spot, shot after shot, no matter what you throw at it. This critical consistency is what we call zero retention. It’s the confidence that lets you pull your rifle out of a case after a rough ride and know your point of aim is still your point of impact.

Every time you fire, the rifle unleashes a violent, split-second force known as recoil. That energy rips through the entire system—from the action, to the Picatinny rail, through your scope rings, and right into the scope. Flimsy, low-quality rings will flex, shift, or loosen under that stress, causing your zero to wander. But a quality set of rings is engineered to absorb and manage that energy without budging a hair.

The Physics of a Solid Mount

The secret to unshakeable zero retention is all about fighting the physics of recoil. This is where you see the real difference between cheap mounts and premium ones, with features like integrated recoil lugs and precision machining stepping into the spotlight.

A recoil lug is a solid, square-shaped crossbolt designed to fit snugly into a Picatinny rail slot. Think of it like a deadbolt for your scope. It physically blocks the rings from sliding forward or backward when the rifle kicks. Without a beefy lug, the rings can slowly "creep" along the rail over time, causing a gradual—and incredibly frustrating—loss of zero.

It's why the best scope rings for a Picatinny rail often feature oversized lugs and massive crossbolts. They’re built for maximum surface contact with the rail slot, creating a powerful, metal-on-metal lock that simply refuses to give.

Why Torque Specs Are Not a Suggestion

Proper torque is the other cornerstone of solid zero retention. Think of it like tightening the lug nuts on your car's wheel. Too loose, and the wheel wobbles. Too tight, and you risk stripping the bolts or damaging the rim. Scope rings work on the exact same principle.

If you don't apply enough torque, the scope can slip inside the rings or the entire mount can shift on the rail. On the flip side, over-tightening can crush the scope tube, messing with the delicate internals and hurting your optical clarity. The goal is to hit that "just right" clamping force defined by the manufacturer.

A torque wrench isn't an optional tool; it's a mandatory piece of gear for mounting a scope correctly. Following the manufacturer’s inch-pound (in/lb) specs is the only way to guarantee a secure mount without damaging your expensive optic.

This is where premium rings really earn their keep. Their high-grade materials and precisely cut threads are designed to handle proper torque values without failing, providing a death grip on the scope tube without stressing it.

The Importance of Precision Machining

Finally, the manufacturing process itself plays a huge role in holding zero. The very best scope rings are often machined as matched pairs. This means the top and bottom halves of a single ring are cut from the same block of metal and stay together through the entire production process.

It’s a painstaking method, but it guarantees the two halves are perfect mirror images. When joined, they form a perfectly circular inner diameter. This perfect circle gives you even, 360-degree contact with the scope tube, eliminating stress points and maximizing grip.

Top-tier Picatinny scope rings are built on this level of engineering. Testing shows that high-end rings maintain their torque settings—typically 15-18 in/lbs for the ring caps and 45-50 in/lbs for the base clamps—to ensure flawless performance under heavy recoil. This, paired with matched-pair manufacturing, creates perfect coaxial alignment, which is non-negotiable for precision shooting. You can learn more about these critical specifications and their impact on reliability.

This commitment to precision prevents the scope from being bent or torqued when the rings are tightened down, letting the optic perform exactly as its designers intended. It's this combination of a solid recoil lug, precise torque, and flawless machining that separates a good set of rings from a great one.

Matching Scope Rings to Your Shooting Style

Let's get one thing straight: the "best" scope rings don't exist in a vacuum. A set that’s perfect for a heavy benchrest rifle would be a terrible choice for a nimble mountain carbine you have to haul up a ridgeline. The secret is to match the ring's design and material directly to your shooting discipline.

Think of your intended use as your North Star. By figuring out your primary application—whether it's hunting, long-range competition, or tactical work—you can cut through the noise and focus on features that actually make a difference in the real world.

Let's break down how to pick the right rings for three common shooting styles.

For the Backcountry Hunter

When you’re covering miles of steep, rugged country on foot, every single ounce feels like a pound by the end of the day. A backcountry hunter's rifle gets carried far more than it gets shot, making weight reduction priority number one. This is where high-quality aluminum rings really shine.

You’ll want to look for rings machined from 7075-T6 aluminum. This aerospace-grade alloy gives you strength that rivals many types of steel but at a fraction of the weight, which helps fight fatigue on those long treks. A streamlined, low-profile design is also a huge plus, as it’s far less likely to snag on brush, branches, or your pack.

- Key Feature: Lightweight construction.

- Material of Choice: 7075-T6 or 6061-T6 aluminum.

- Design Preference: Slim, snag-free profile with minimal hardware.

The goal here is the perfect marriage of durability and weight savings. You need rings that can handle an accidental drop on a rocky trail but won’t feel like an anchor while you’re climbing to your glassing spot.

For the Precision Competitor

Long-range precision shooting is a game of extremes. You’re managing violent recoil and chasing absolute, repeatable consistency shot after shot. In this discipline, weight is often an advantage, and structural rigidity is completely non-negotiable. This is steel's territory.

Steel rings are simply denser and far less prone to flexing under the heavy recoil of magnum cartridges like the .338 Lapua or .300 PRC. Look for beefy designs with wide ring caps and multiple clamping screws—often six or even eight per ring—to get maximum surface contact and grip on the scope tube. A massive, integral recoil lug is also essential to prevent any movement on the Picatinny rail.

For the precision shooter, the ideal scope rings are overbuilt. They are the anchor of the entire system, engineered to withstand thousands of high-energy recoil impulses without ever shifting, ensuring your zero stays true from the first shot to the last.

These shooters need the most robust foundation they can get. The extra mass of steel helps dampen vibration and provides the brute strength needed for unwavering zero retention during a long, demanding course of fire.

For the Tactical User

The tactical world demands speed and versatility above all else. The ability to rapidly adapt your rifle to changing conditions is paramount, and this is where quick-detach (QD) mounting systems become incredibly valuable.

Instead of nuts or screws, QD rings use levers to clamp onto the Picatinny rail. This allows an operator to pop a magnified optic off in seconds to switch to a red dot for close-quarters work or to use backup iron sights if the primary optic fails. High-quality QD mounts are engineered for excellent return-to-zero performance, meaning you can remove and reinstall the scope without a significant shift in your point of impact.

The demand for adaptable mounting options often follows seasonal shooting activities. For instance, search interest for "picatinny rail scope mount" tends to peak in the fall, rising from a search volume of 14.8 in June to 20.8 by October. During that same period, average sales increase from 133.7 to 183.65 units. You can learn more about seasonal trends in Picatinny rail mount demand.

Ultimately, matching your rings to your shooting style ensures every component on your rifle is working toward the same goal. It’s the difference between a system that works for you and one you have to fight against.

Your Final Checklist for Choosing Scope Rings

Choosing the right scope rings for a Picatinous rail doesn't have to be complicated. When you break it down into a few clear, logical questions, the perfect choice becomes obvious.

This final checklist is designed to walk you through that decision-making process, pulling together everything we've covered into a practical, step-by-step guide. Answer these questions honestly, and you’ll be able to confidently pick a set of rings that perfectly matches your rifle, your scope, and how you actually shoot.

Think of it this way: this isn't just about buying another part. It's about completing a high-performance system. A poorly chosen set of rings can undermine even the most expensive rifle and optic, turning a precision setup into a frustrating mess.

Key Questions to Ask Yourself

Before you click "add to cart," run through this quick mental inventory. It’ll make sure you don't overlook a critical detail that could come back to haunt you down the road.

-

What's this rifle's main job? Is it a lightweight rig for hauling up a mountain, a heavy bench gun for punching tight groups, or a do-it-all carbine? Your answer here immediately points you toward either lightweight aluminum or ultra-tough steel rings.

-

What's my scope's tube diameter? Is it a 1-inch, 30mm, or 34mm? This is the first, non-negotiable measurement. Get it wrong, and nothing else matters.

-

How big is my scope's objective lens? This number, combined with your rifle's barrel profile, is what determines the ring height you need. The golden rule is to always mount the scope as low as possible while still giving the objective lens enough clearance over the barrel.

-

Do I actually need a quick-detach (QD) system? If you swap optics often or want fast access to backup iron sights, a QD mount is a game-changer. But for a "set it and forget it" build, standard rings are simpler, often more robust, and less expensive.

By methodically working through this checklist, you move beyond guesswork and start making an informed engineering choice. The goal is to create a seamless connection between your eye, your scope, and your rifle, ensuring the entire system performs as one cohesive unit.

Answering these questions ensures your final choice is truly tailored to your specific gear and mission. You're now fully equipped to select the ideal scope rings, ensuring your shooting system is locked in for peak performance and unwavering reliability when it counts.

Got Questions About Picatinny Scope Rings? We Have Answers.

Even after you've nailed down the basics, a few specific questions always pop up when it's time to choose the best scope rings for a Picatinny rail. Getting a straight answer can save you from a costly mistake and ensure you’re building a rock-solid shooting platform from the get-go.

Let's clear the air and tackle some of the most common questions we hear.

Are Picatinny and Weaver Rings the Same Thing?

This is probably the number one point of confusion out there. They look almost identical, but Picatinny and Weaver rails are not perfectly interchangeable. The real difference is in the recoil slots—those square grooves cut across the top of the rail.

Picatinny rails are built to a strict military standard, with slot widths of 0.206 inches and perfectly consistent spacing. Weaver rails, on the other hand, have narrower slots (0.180 inches), and the spacing between them can be irregular.

Here’s what that means for you in the real world:

- Picatinny rings WILL fit on Weaver rails. Their crossbolts are made to accommodate the narrower Weaver slots.

- Weaver rings will NOT always fit on Picatinny rails. The wider Picatinny slots are often too big for the Weaver crossbolts to lock into, leaving you with a loose, unreliable mount.

When in doubt, always match your rings to your rail. It’s the only way to guarantee a secure, no-compromise fit.

Do I Really Need a Torque Wrench?

Yes. This isn't just a friendly suggestion—it’s a mandatory step for mounting a scope correctly. A torque wrench lets you apply the exact amount of force the manufacturer specifies, and that’s critical for two huge reasons.

First, under-tightening is an invitation for your zero to wander. Recoil will eventually cause your scope to slip in the rings or the whole mount to shift on the rail. Second, and much worse, over-tightening can literally crush your scope tube. This can cause permanent, irreparable damage to the delicate lenses and internal mechanics of your expensive optic.

Think of it like this: you want a firm handshake, not a bone-crushing grip. Most ring makers recommend 15-18 in/lbs for the ring caps and 45-50 in/lbs for the base clamps. Guessing is a gamble you don’t want to take.

Should I Lap My Scope Rings?

Lapping is the old-school process of using a steel bar and an abrasive paste to polish the inside of scope rings, making them perfectly round and aligned. Years ago, when manufacturing wasn't as precise, this was often a necessary evil to keep the rings from putting uneven stress on the scope tube.

But today? With modern CNC machining, high-quality rings are made as matched pairs with incredibly tight tolerances. For any reputable, precision-machined rings, lapping is completely unnecessary. In fact, you can actually do more harm than good by removing material or stripping the protective finish, which could even void your warranty.

Invest in a quality set of rings from a trusted brand, and you can skip the lapping kit. They're ready to go right out of the box.

At Magic Eagle, we know that dependable gear is the cornerstone of every successful hunt. Our cellular trail cameras are engineered with that same commitment to precision and reliability, giving you clear, real-time intel from the field when you need it most. See how our smart camera technology can sharpen your scouting edge at https://magiceagle.com.